A powerful and robust sliding system that allows for large openings at a competitive price and with aesthetics adapted to the latest trends.

The panoramic crossing option of only 26 mm gives the system a minimalist character, as well as a larger glazed surface. The options of stainless steel tracks and integrated locks increase the mechanical performance. The use of TRI-FIN weatherstripping combined with sealing gaskets on the sides and the powerful “Lift-and-Slide Channel” achieve better acoustic and thermal performance. The use of the “WSS” increases water permeability up to class 7A. Possibilities include perimeter-cut, panoramic, or straight sash configurations.

TECHNICAL FEATURES

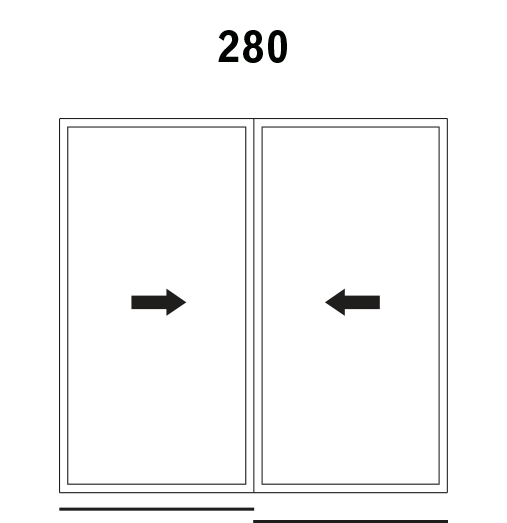

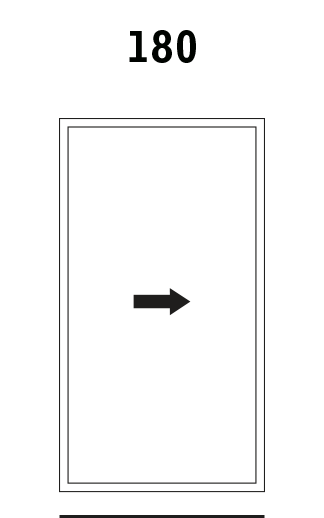

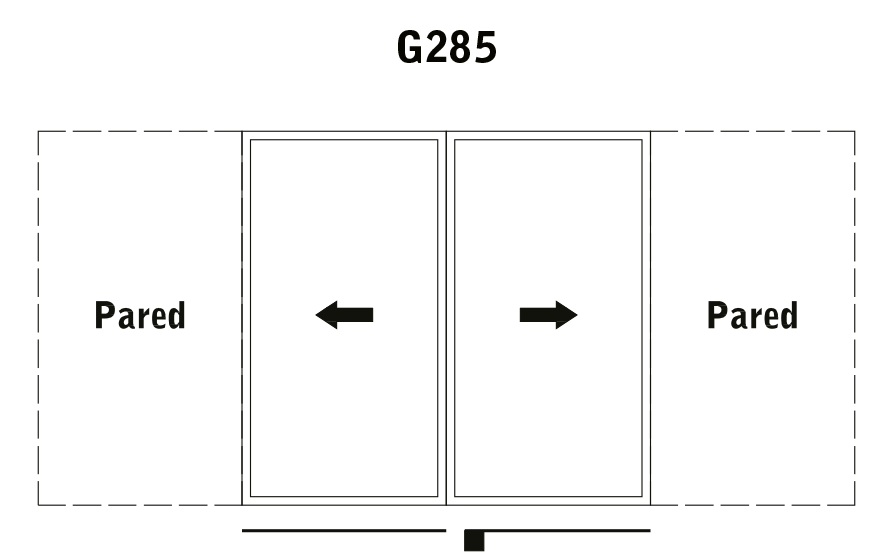

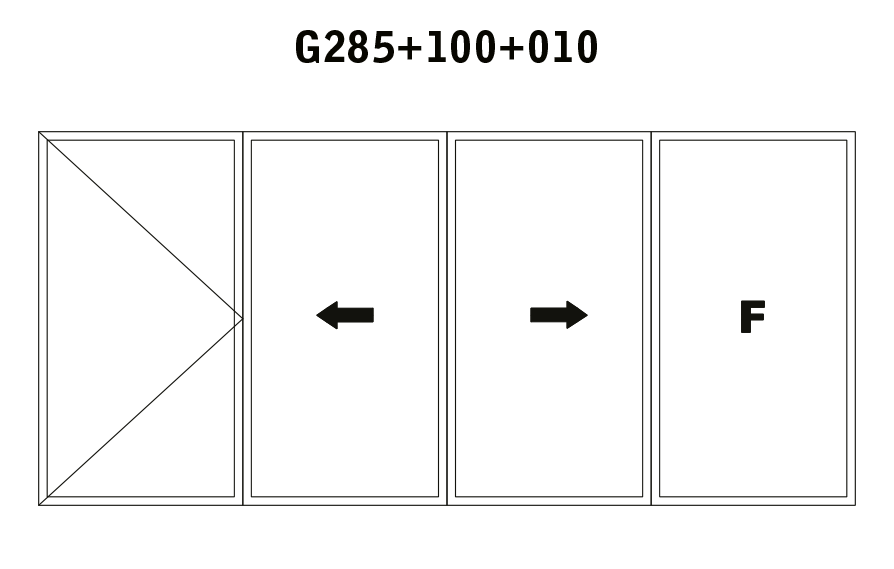

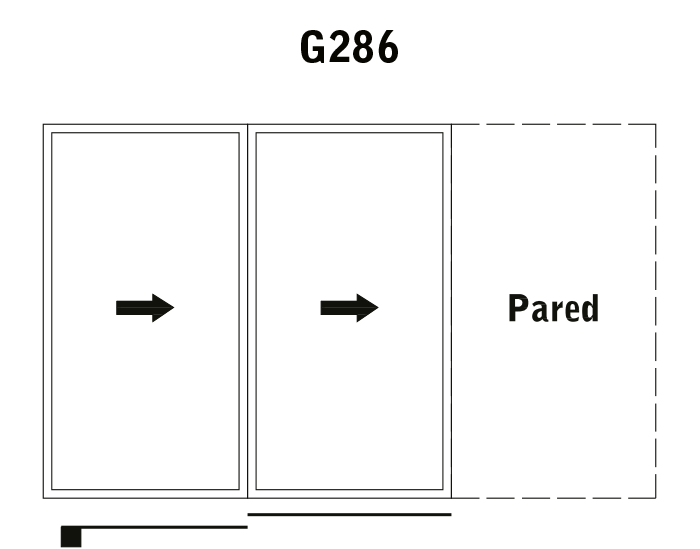

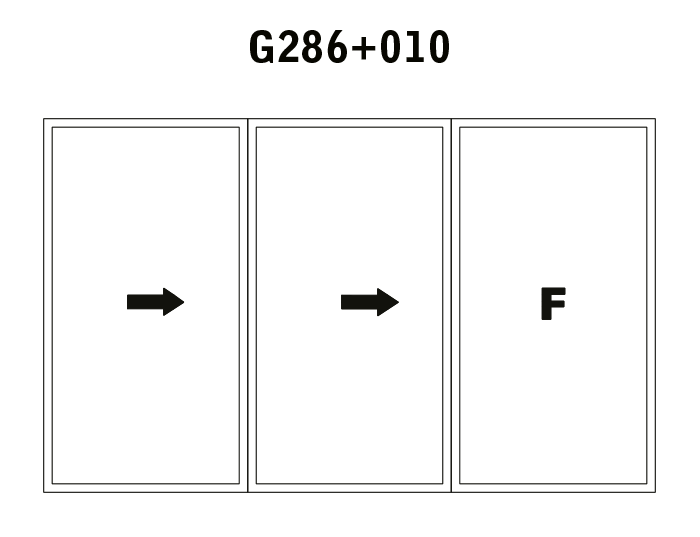

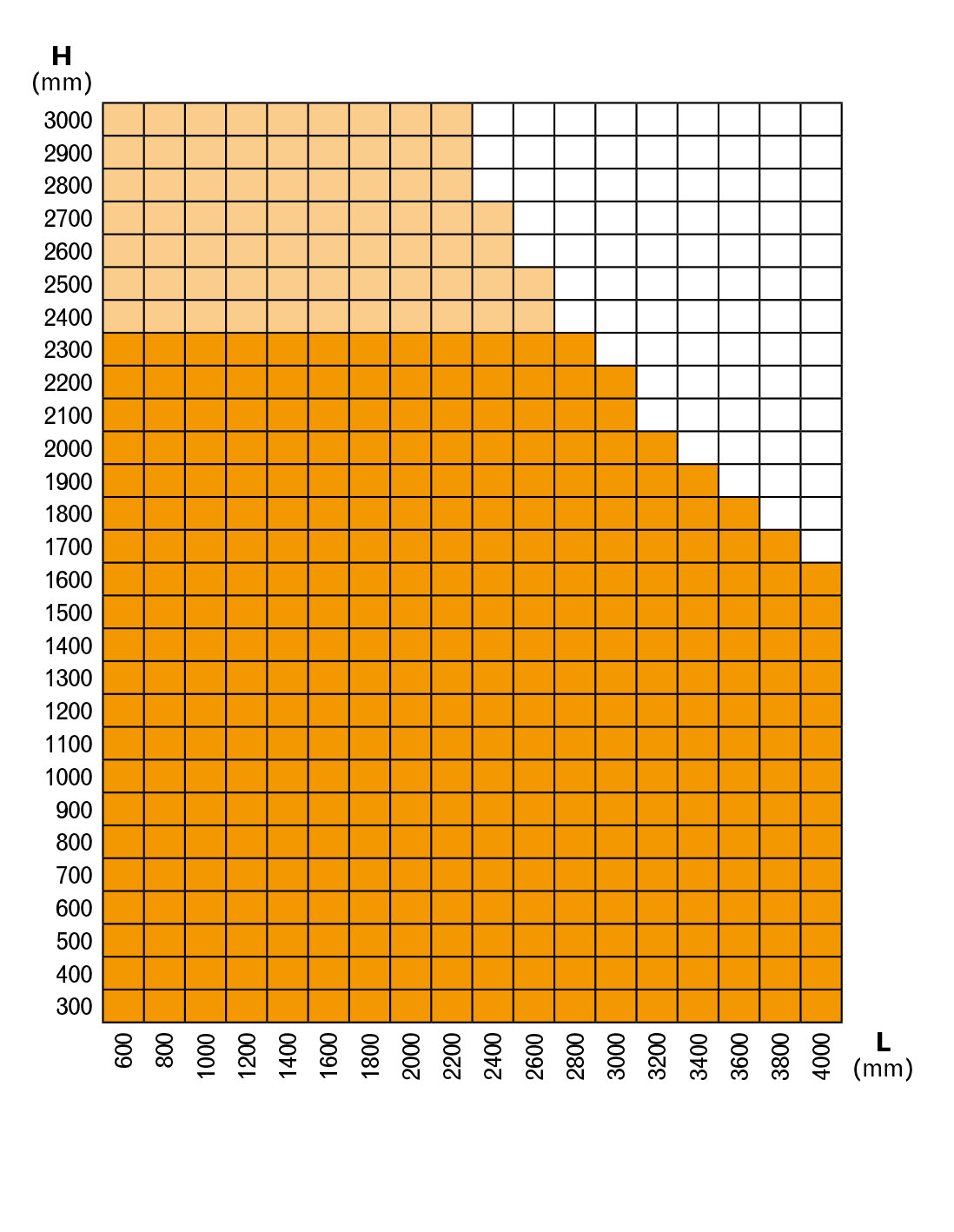

Sliding system with thermal break (RPT) and a 95 mm frame that offers good performance in testing laboratories and fast, simple manufacturing. Especially suitable for sliding windows and balcony doors up to 2300 mm.

Test results in laboratory:

According to the Technical Building Code (CTE), this series is suitable for all climate zones, although in zones D and E it is recommended to use insulating glass.

Innovations and technical details:

To improve sealing and thermal/acoustic insulation, the system includes a patented inverted U-shaped polyamide profile that allows drainage along the entire length of the bottom frame—not just the exterior-facing section. This innovation is patented and incorporated across the entire range of sliding systems.

Bearings use needle rollers and come in both single and tandem versions. All are vertically adjustable, and the tandem version supports up to 150 kg per sash. Bearings can be replaced without opening the sash. For more information on bearings, visit: www.woorbel.com

The frame profiles feature a clipping system that allows for easy positioning of auxiliary profiles such as trim caps, drip edges, or frame connectors.

Innaltech supplies the complete range of accessories for this system. All our systems are digitally integrated in terms of material breakdown, cutting optimization, manufacturing sheets, and CE marking labels. Automation of cutting and machining at machining centers is also possible. The software is available in Spanish, Catalan, and French.

AEV Tests Performed

| Window | Test Report | Air | Water | Wind |

| 2000 x 1500 mm 2-leaf perimeter | 09/100329-445 (APPLUS) | 3 | 5A | C4 |

| 2900 x 2300 mm 2-leaf perimeter | 09/100329-440 (APPLUS) | 3 | 4A | C1 |

| 2900 x 2100 mm 3-leaf perimeter | 09/100329-1003 (APPLUS) | 3 | 5A | C1 |

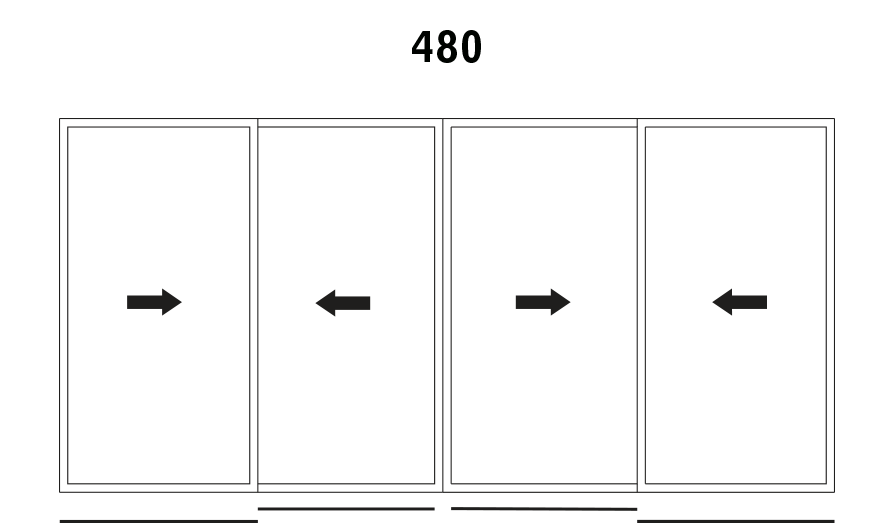

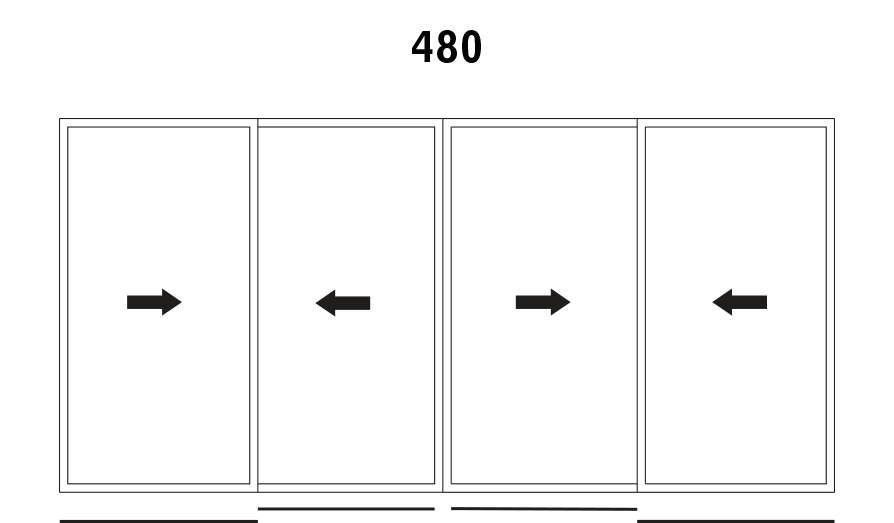

| 2900 x 2100 mm 4-leaf perimeter | 09/100329-1004 (APPLUS) | 3 | 4A | C1 |

| 2900 x 2100 mm 2-leaf straight | 11/2284-3093 (APPLUS) | 3 | 7A | C1 |

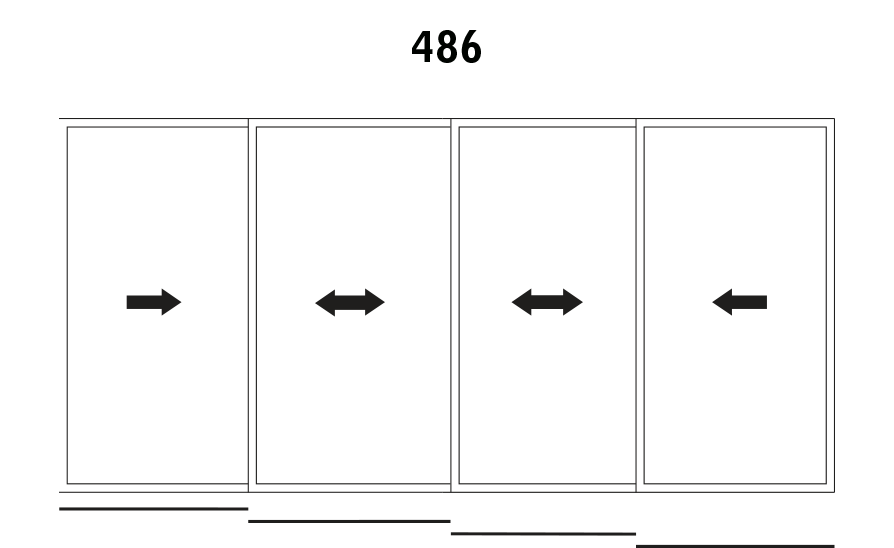

| 2900 x 2100 mm 2-leaf panoramic | 11/2284-2674 (APPLUS) | 3 | 7A | C1 |

Acoustic Tests

| Window | Test Report | Result (dB) |

| 1400 x 1500 mm 2-leaf glass 4/16/4 | 10/101124-46 (APPLUS) | 31 |

| 1400 x 1500 mm 2-leaf glass 3+3/10/6 | 10/101124-45 (APPLUS) | 33 |

Thermal Tests – Frame

| Frame | Test Report | Result (W/m2K) |

| Perimeter joint | 25130-13 (CIDEMCO) | 3,7 |

| Reinforced central joint | 25130-14 (CIDEMCO) | 6,0 |

| Reinforced central joint 4-leaf | 25130-15 (CIDEMCO) | 3,5 |

| Panoramic central joint | Internal | 4,1 |

Thermal Tests – Window according to CTE

| Window | Result (W/m2K) 4/14/4 (Ug=2,8) |

Result (W/m2K) 4/14/4 BE* (Ug=1,5) |

Result (W/m2K) 4/16 Ar/4 BE** (Ug = 1,1) |

| 2-leaf perimeter window 2000 x 1500 mm | 3,17 | 2,24 | 1,96 |

| 2-leaf perimeter window 2900 x 2300 mm | 3,01 | 1,97 | 1,70 |

| 4-leaf perimeter window 2900 x 2300 mm | 3,13 | 2,20 | 1,97 |

| 2-leaf panoramic window 2000 x 1500 mm | 3,07 | 2,11 | 1,79 |

| 2-leaf panoramic window 2900 x 2300 mm | 2,98 | 1,92 | 1,57 |

| 4-leaf panoramic window 2900 x 2300 mm | 3,01 | 1,98 | 1,62 |

| * Low emissivity ** Thermal result obtained by applying Foam Isolation System on the sash |

|||

Straight-cut panels NT95 6577 / NT95 6660. It is advisable to use the NT95 657R / NT95 666R reinforcement profile

Straight-cut panels NT95 6577 / NT95 6660. It is advisable to use the NT95 657R / NT95 666R reinforcement profile Panoramic panels NT95 6690. It is advisable to use the NT95 659R / KR4020 reinforcement profile

Panoramic panels NT95 6690. It is advisable to use the NT95 659R / KR4020 reinforcement profile