Nexus 100 RPT is the sliding system that perfectly combines contemporary aesthetics, the capacity for large openings, the strength to support heavy weights, and the ability to accommodate high-performance thermal and acoustic glass. All this with cutting-edge technological innovation, the best components, and in line with current architectural and interior design trends. Nexus 100 RPT is a high-performance enclosure at a competitive price.

Perimeter sliding system with thermal break (RPT), featuring a double working corner on the sash, yet light and aesthetic thanks to a panoramic crossing of only 37 mm. It allows glass up to 38 mm thick in its closed sash version, including the possibility of installing double insulating “TRIPLEX” glass. It also offers the option of beaded sashes, greatly facilitating installation.

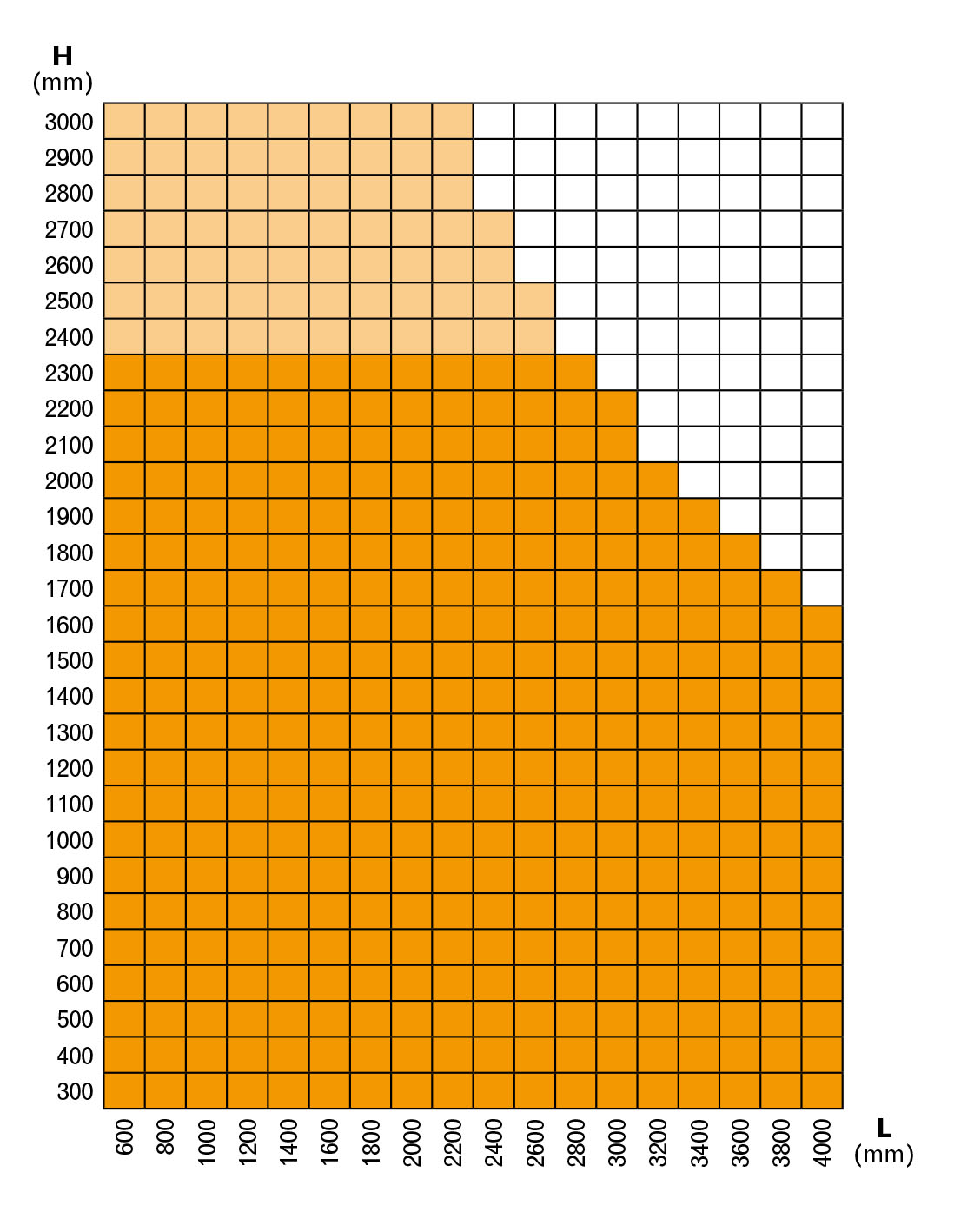

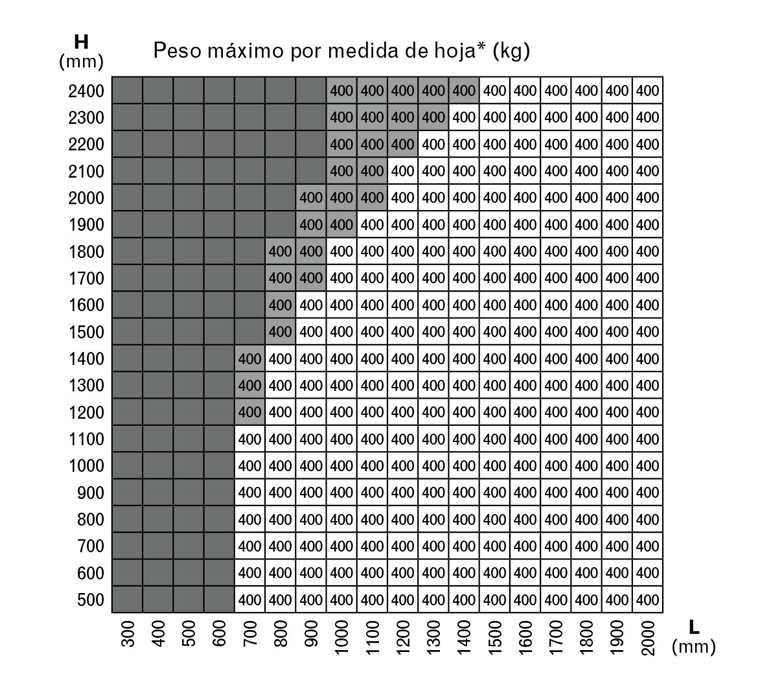

Its powerful bearings match the significant glass weights Nexus 100 RPT can handle, supporting weights close to 400 kg per sash. The frame can be reinforced with a specific accessory for this purpose. Bearings glide smoothly on stainless steel tracks, preventing unnecessary wear on both tracks and bearing wheels. For more information about the bearings, visit www.woorbel.com.

The innovative PVC “totem” system located in the center of the frame enhances the RPT functions of the system. It also allows for an additional sealing brush between the frame and sash. Laterally, the sash allows for the installation of sealing gaskets. All this contributes to improved watertightness and airtightness.

Simultaneously, the “totem” system eliminates the need for the traditional, cumbersome windbreakers on the frame. These are located on the central covers of the panoramic crossing, which are installed at the very end of the assembly process, once the entire enclosure is finished. This innovation greatly improves the assembly and adjustment process of the sliding system.

Innaltech supplies the complete range of accessories for this system. All our systems are fully integrated with software for material breakdown, cutting optimization, manufacturing sheets, and CE marking labels. Automation of cutting and machining in machining centers is also possible. The software is available in Spanish, Catalan, and French.

Nexus 100 RPT sashes feature the innovation of self-sliding polyamides. These are capable of channeling and absorbing the harmful effects of differential expansions between the interior and exterior of the building, significantly reducing sash warping problems and their known negative consequences. Considering the price difference, this is a recommended option to avoid future issues.

Nexus 100 RPT offers the option to include the “Raised Channel” feature (patented by Grifell Pons, SL). This proven system significantly improves thermal and acoustic coefficients and greatly enhances water tightness performance. The “Raised Channel” in Nexus 100 RPT is now in its second generation, doubling its placement within the PVC “totem.”

The enclosure uses a multipoint locking system with hooks that engage into a fully integrated stainless steel plate inside the frame, smooth and flush with no protrusions. The multipoint system features “anti-false maneuver” technology. The operating handles open to 20º, facilitating the sliding sash’s push.

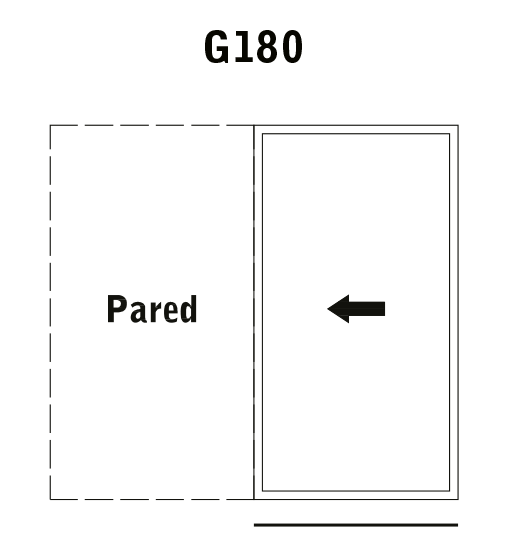

Nexus 100 RPT also allows for embedding the frame into the floor and walls. This option includes specific premounted frames with RPT. The water drainage and channel systems can be used independently of whether these premounted frames are installed. This option provides better ergonomics and relationship between the home and sliding enclosure, giving the whole system greater functionality and spatial openness.

Nexus 100 RPT has a minimalist aesthetic that emphasizes light, space, and vision. This effect is achieved by increasing glass area and reducing central structural elements. The front of the frame is completely smooth, and the sashes overlap the frame, giving the sliding door an appearance very close to a hinged door, unifying all home enclosures’ styles.

Innaltech supplies the complete range of accessories for this system. All our systems are fully integrated with software for material breakdown, cutting optimization, manufacturing sheets, and CE marking labels. Automation of cutting and machining in machining centers is also possible. The software is available in Spanish, Catalan, and French.

Test Bench Performance:

According to the CTE (Technical Building Code), which requires minimum thermal performance depending on geographic location, this series is suitable for all climate zones, though in zones D and E insulating glass will be required.

To increase watertightness and thermal and acoustic insulation, it features an inverted U-shaped polyamide profile that drains along the entire length of the lower frame, not only on the exterior side. This patented innovation is present throughout the sliding range.

The bearings use needles and are available in single and tandem versions. All can be vertically adjusted, and the tandem version can support up to 200 kg per sash. Bearing replacement can be done without opening the sash. For more info, visit www.woorbel.com.

Frame profiles include a clipping system that allows easy positioning of auxiliary profiles like trims, drip caps, or frame joints.

Innaltech supplies the full range of accessories for this system. All our systems are computer-integrated, including material breakdown, cutting optimization, manufacturing sheets, and CE marking labels. Cutting and machining can also be automated on a machining center. The software is available in Spanish, Catalan, and French.

| Window | Test Report | Air | Water | Wind |

| 2000 x 1500 mm, 2 perimeter sashes | Internal | 3 | 7A | C4 |

| 2000 x 2300 mm, 2 panoramic sashes | Internal | 3 | 7A | C1 |

Window Acoustic Tests

| Window | Test Report | Result (dB) |

| 1400×1500, 2 sashes, glass 4/16/4 | Internal | 32 |

| 1400×1500, 2 sashes, glass 4+4/16/6 | Internal | 34 |

Frame Thermal Tests

| Frame | Test Report | Result (W/m2K) |

| Perimeter joint | Internal | 3,5 |

| Result (W/m2K) | |||||

| Window | 4/16/4 (Ug=2,8) | 4/16/4 BE (Ug=1,5) | 4/16 Ar/4 BE (Ug = 1,1) | 4/12/4/12/4 BE** (Ug = 0,7) | 3+3CS/16A/4/16A/4BE** (Ug = 0,5) |

| 2 perimeter sashes 2000 x 1500 mm | 3,25 | 2,29 | 1,99 | 1,69 | 1,19 |

| 2 perimeter sashes 2900 x 2100 mm | 3,13 | 2,07 | 1,74 | 1,42 | 0,99 |

| 2 perimeter sashes 2900 x 2300 mm | 3,12 | 2,05 | 1,72 | 1,39 | 0,97 |

| * BE = Low Emissivity ** The thermal result has been obtained by installing the Foam Isolation System on the sash |

|||||